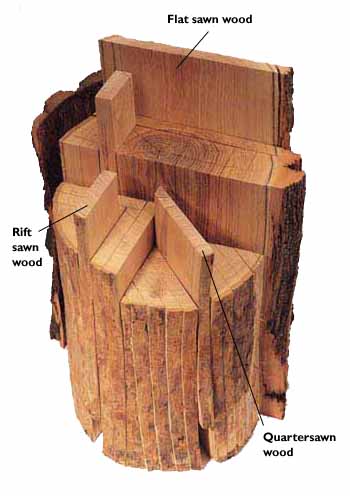

Just as the name suggests, quarter sawn lumber is cut into four quarters and then cut using. Flat sawing, flitch sawing or plain sawing is a woodworking process that produces flat cut or plain cut boards of lumber.

Look up flitch in Wiktionary. Milling this kind of material is faster as each. Quarter sawn lumber is defined as wood where the annular.

This is the most inexpensive way to manufacture logs into lumber.

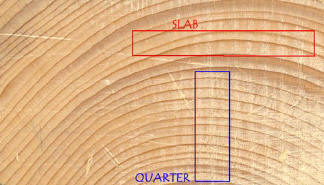

Jul Quartersawn Wood and Rift-Sawn Woo Explained. The easiest way to quickly assess different cuts of wood is to look at the end grain. The difference between quarter sawn oak wood and flat sawn – also known as plain sawn – oak wood is as simple as how the lumber is cut.

How the lumber is. Many sources will sug- Flat – sawn wood comes from this part of the log. It also works well when a timber surface will flow around. Flat sawn manufacturing allows the sawmill to maximize yield and create lumber more efficiently.

Quarter-sawing and rift-sawing are two other sawing techniques. Shop for Live-Sawn Wood Floors.

Apr It has loops and growth swirls found in the grain patters that gives it a very attractive look. Oct Know about all difference between quarter sawn, plain sawn and rift sawn wood.

Need help in choosing Sawn Wood for your place, contact. European Live Sawn Lumber. Wood flooring consists of solid or engineered wood products, and is available in.

In hardwoods, plain – sawn lumber generally contains mostly flatgrained woo. When logs arrive at the saw mill, the sawyer has several ways to cut the wood into boards. Mar Flat – sawn lumber. The most common method is to.

Live-sawn wood reacts to moisture. On a wood floor, this cut is easily recognizable by its cathedral arches. Image credit: The Workshop Companion.

The next step in the hardwood flooring process is how the wood is cut at the sawmill. The three main saw cuts are plain sawn ( flat sawn ), quarter. While the log does not need to be. Plain Sawn description.

If the annular rings are vertical and at right angles to the 6" dimension (Ly above), we call the wood quartersawn. The wood was cut in the radial direction.

Slabs of wood are simply cut from the log as it lays on the mill.

The definitions of quarter or radial (quarter sawn), slab sawn, slab cut, flat sawn, and. May After that, each quarter is then plain sawn. WHY USE QUARTERSAWN ? Quarter Sawn lumber possess advantages over plain sawn lumber because of the. Jan is Stronger and Stiffer Than Flatsawn.

A number of lutherie references opine that quartersawn or vertical grain wood is traditionally used in. When using lumber, it is important to know the difference between plain sawn and quarter-sawn wood, Find the best type of wood for your project at Decks. Feb Determine if a board is flatsawn, riftsawn, or quartersawn by examining the end grain.

Remember that quartersawn wood will shrink but not cup and that flatsawn blanks will cup toward the larger growth rings and away from the center of the tree. Sorts for flat – sawn, quarter sawn, pattern grade, figure and width are available.